PCBN Materials

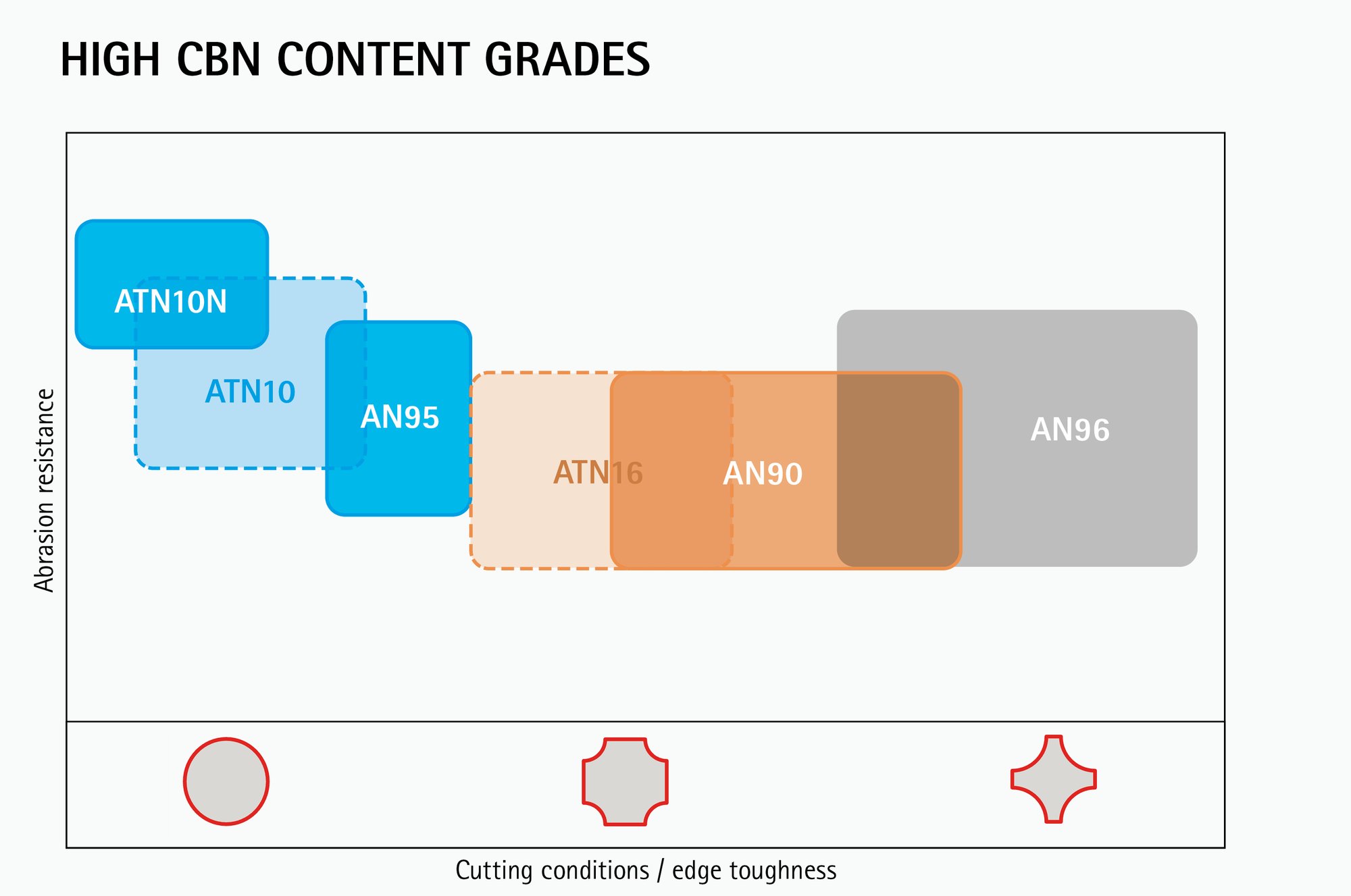

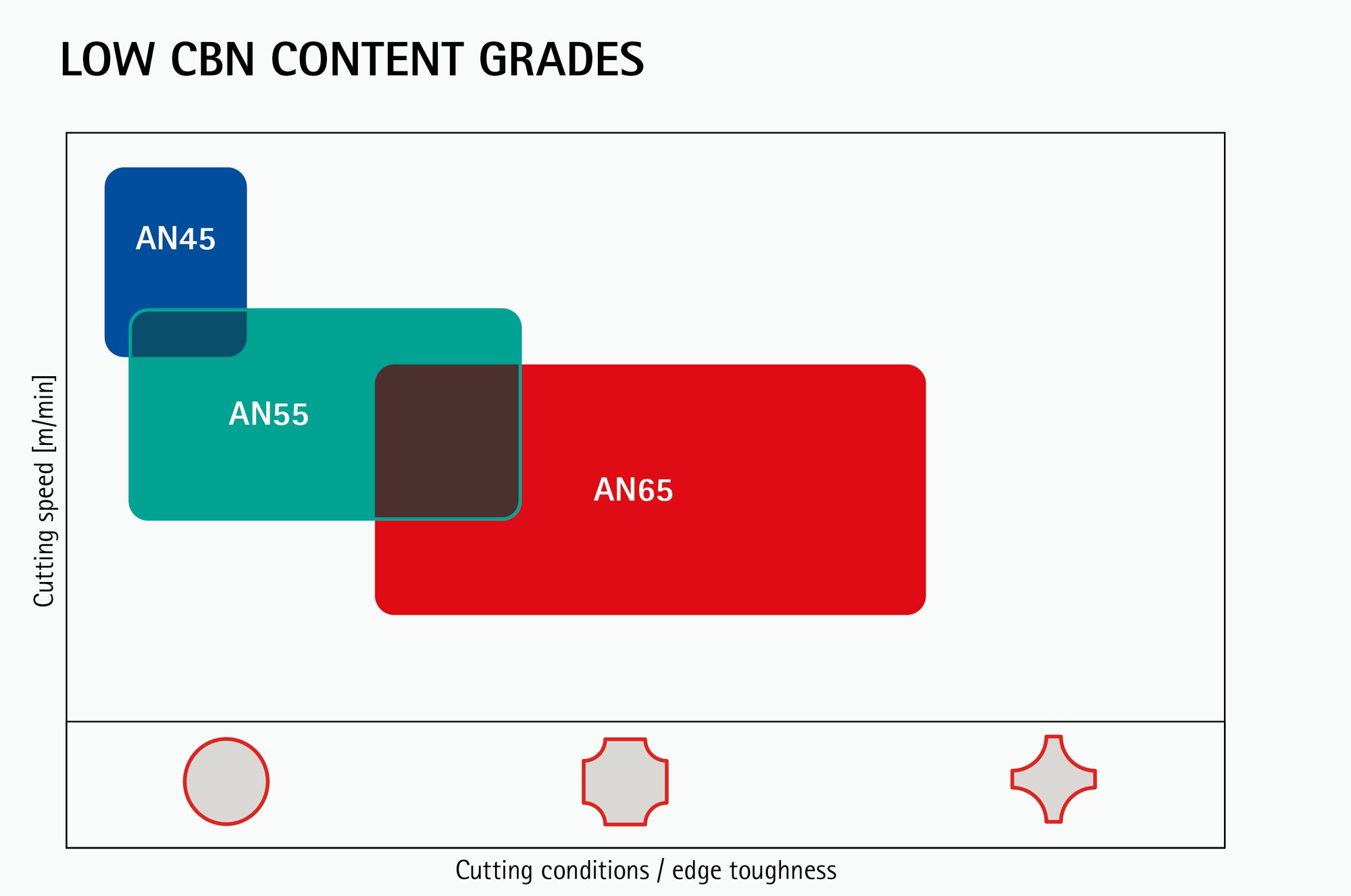

ADICO PCBN products are largely divided into high CBN content and low CBN content, and also classified into fine-grained PCBN and coarse-grained PCBN as well.

| Grade | CBN-Content [vol%] |

CBN-Size [µm] |

Main Binder | Application | Micro Structure |

| AN96 | 96 | 1 | Metal (Co, Al, X) |  |

|

| AN95 | 95 | 2 | Metal (Co, Al, X) |  |

|

| ATN10 | 95 | 3 | Metal (Co, Al) |  |

|

| ATN10N | 95 | 3 | Metal (Co, Al, X) |  |

|

| AN90 | 90 | 1 | Metal (Co, Al, X) |  |

|

| ATN16 | 90 | 1 | Metal (Co, Al) |  |

|

| AN65 | 65 | 1 | Ceramic (TiN) |  |

|

| AN55 | 55 | 1 | Ceramic (TiCN) |  |

|

| AN45 | 45 | 1 | Ceramic (TiCN) |  |

|

ADICO PCBN Cutting Tool Product Application Areas

| The range of workpiece materials that Adico PCBN can successfully machine is constantly ex-panding, but the main material groups are: |

|||

| 1. Hardened steels 2. Hard facing alloys 3. Chilled cast iron 4. Pearlitic grey cast irons |

5. Sintered iron 6. Superalloys e.g. Inconel 718 7. Powder metal e.g. automotive valve seats |

||

| ADICO PCBN Products | Successful machining applications have been established in the automotive, aerospace, and manufacturing industries, and some examples are: |

||

| High CBN-content PCBN | |||

| AN96 |

|

||

| AN95, ATN10, ATN10N |

|

||

| AN90, ATN16 |

|

||

| Low CBN-content PCBN | |||

| AN65 | moderate to heavy interrupted hard turning, finish hard milling | ||

| AN55 | continuous & slight interrupted turning of hardened steels | ||

| AN45 | high speed finish turning on hardened steels | ||

3 different ADICO PCBN product configurations

| ATN-series (Single PCBN-layer) |

ADN-series (Double PCBN-layer) |

ASN-series (Solid PCBN-layer) |

|

|

|

| Blank Sizes: Blank thickness (mm): 1.6, 2.0, 2.4, 3.2, 4.8 ± 0.05 PCBN thickness (mm): 0.75 ± 0.15 |

Available on request | Available on request |

We develop the perfectly adapted PCD or PcBN cutting material specifically for our customers' applications.

Together we will find the perfect solutions for your challenges.

Philipp Homann

Phone: +49 151 63421083

philipp.homann@adico-polydiamond.com